WE ARE THE WORLD'S LEADING TEC MODULE SUPPLIER WITH THE

MOST COMPLETE SERIES AND LARGEST STOCKING INVENTORY.

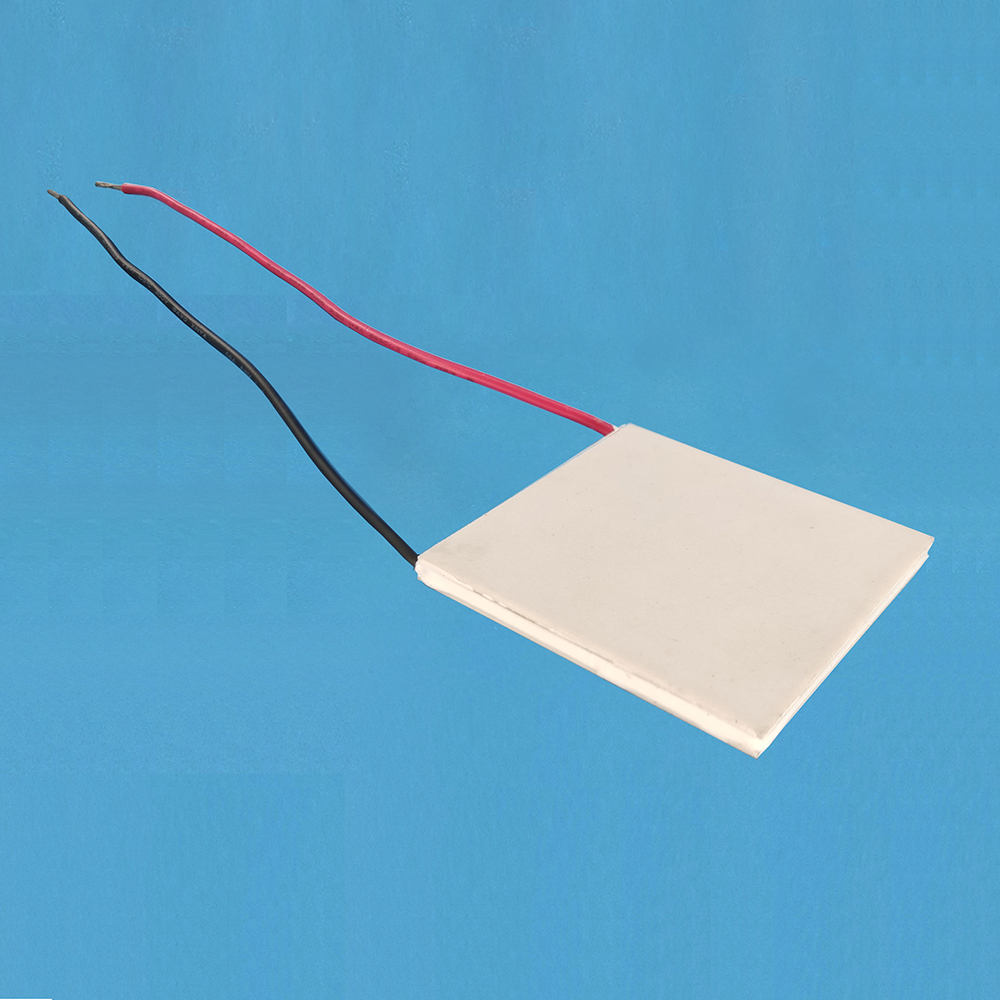

Thermoelectric coolers (TECs), also known as Peltier coolers, thermoelectric modules, or TEC modules, are versatile devices capable of generating both heating and cooling effects by applying an electric current, depending on its direction. When the current flows in one direction, one of the Peltier cooler plates heats up while the other cools down. Reversing the current causes the TEC plates to switch their thermal polarity. TEC modules find applications in various fields, with a prime example being the precise temperature regulation of laser diode chips. This regulation ensures the emission of stable laser beams with a consistent wavelength and minimal optical noise.

Selecting the Right TEC Modules

When designing a temperature regulation system based on TECs, choosing the appropriate TEC module is crucial. Here are some general guidelines:

1. TEC Lifespan: TECs have a limited lifespan, which can be measured by monitoring the relative change in their AC resistance. Once the AC resistance increases by 10%, the TEC is considered at the end of its useful life. This increase in resistance is due to the expansion and contraction of the internal semiconductor elements, known as Peltier elements. This expansion and contraction lead to micro cracks inside the elements, raising the AC resistance and reducing cooling efficiency. Frequent current reversals can accelerate this process, ultimately leading to the TEC's failure. Regular TECs can endure up to 1,000 times full-scale current reversals before reaching the 10% resistance increase threshold, while our long-life TECs can withstand up to 20,000 such reversals for the same resistance increase. For applications that require frequent full-scale current reversals, such as thermal cyclers for PCR tests, long-life TECs are recommended.

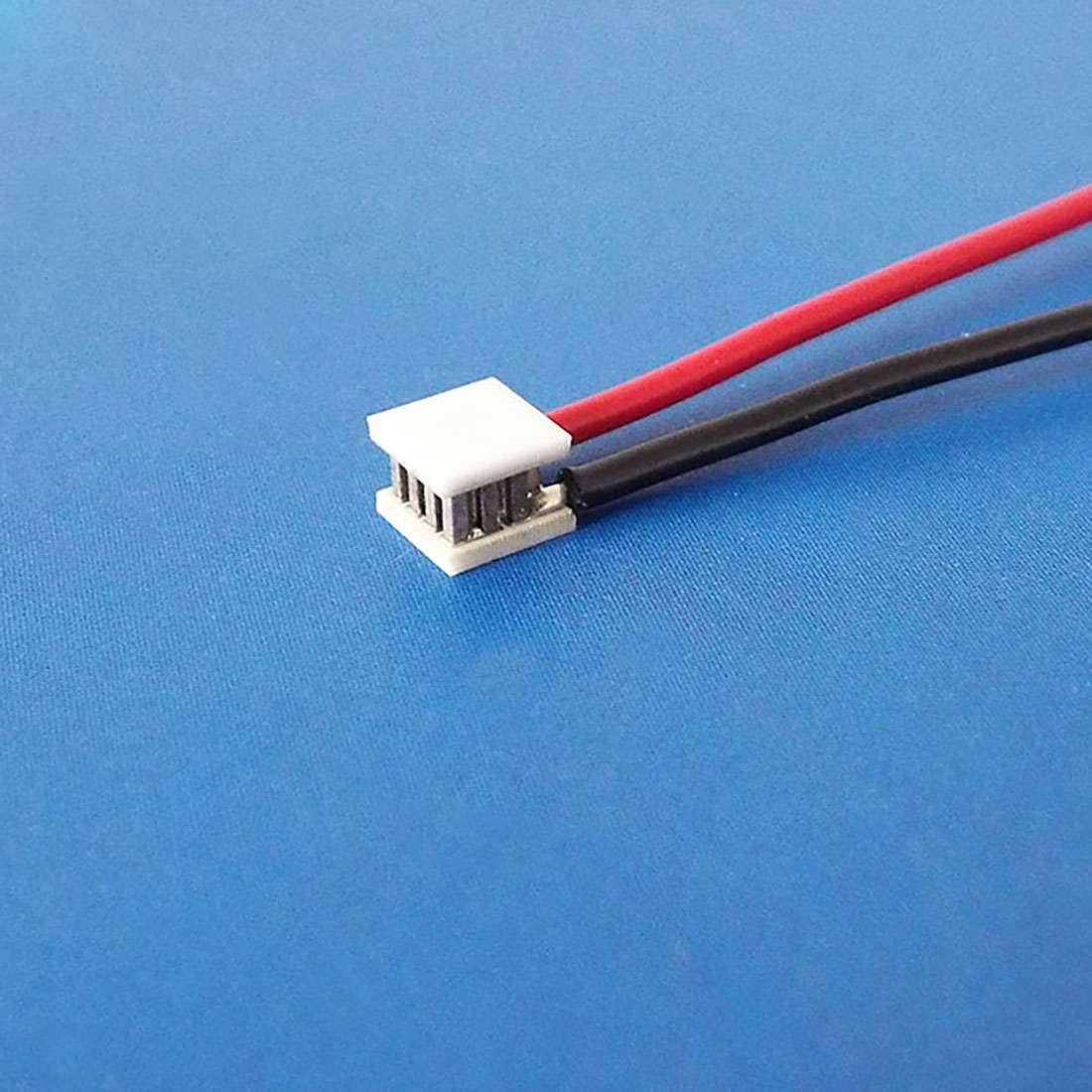

2. AC Resistance Measurement: To monitor the AC resistance, use specialized meters. We offer a dedicated meter (TH2810D) for this purpose.

3. Minimize Delta T: To enhance the overall system efficiency, known as the Coefficient of Performance (COP), it's crucial to minimize the temperature difference (delta T) between the two TEC plates. Achieve this by using a sufficiently large heat sink or adding a powerful cooling fan to the hot side TEC plate. This reduces the operation temperature and lowers delta T. We recommend a maximum delta T of <30℃ to achieve a COP >1 or even 2. Refer to our TEC module datasheets for precise values and further details.

4. Avoid Sheer Force: TEC modules are sensitive to sheer forces, which can lead to the breakage or cracking of the internal semiconductor elements. While TEC modules can withstand high compressive forces, typically between 25 psi to 100 psi (pounds per square inch), avoid applying sheer force to ensure their longevity and efficiency.

5. Gentle Current Switching: When controlling TEC current, avoid hard switching methods that result in sudden temperature changes within the semiconductor elements. These abrupt changes can create internal cracks. The best approach is to use smoothed, slow-changing DC current. The second-best method is to employ Pulse Width Modulation (PWM) current with a frequency of ≥1kHz, with higher frequencies being advantageous, although they may reduce driver efficiency.

6. Selecting Appropriate Mounting Methods:

There are three commonly used methods for mounting TEC modules: compression with thermal grease, adhesive bonding, and soldering. The first method is the most commonly used due to its cost-effectiveness and increased sheer force resistance. The second method is suitable for small devices, such as TECs for cooling laser diode chips. The third method offers the best performance but is vulnerable to sheer force or shock. We recommend using the first method for large assemblies (≥30mm×30mm) with a focus on cost-effectiveness, the second method for small assemblies (≤20mm×20mm), and the third method for high-performance, long-life small assemblies. Feel free to contact us for free consultations.

Thermoelectric coolers (TECs), also known as Peltier coolers, thermoelectric modules, or TEC modules, are versatile devices capable of generating both heating and cooling effects by applying an electric current, depending on its direction. When the current flows in one direction, one of the Peltier cooler plates heats up while the other cools down.

Analog Technologies has a long history of developing high-quality laser drivers, with over 100 diferent types of drivers released to theworldwide market since 1997. Our drivers have earned a reputation for their small size, low noise, high eficiency, and low cost, making them ideal for a wide range of applications. Our laser drivers are u

Analog Technologies has a long history of developing high-quality laser drivers, with over 100 diferent types of drivers released to theworldwide market since 1997. Our drivers have earned a reputation for their small size, low noise, high eficiency, and low cost, making them ideal for a wide range of applications. Our laser drivers are u

Analog Technologies has a long history of developing high-quality laser drivers, with over 100 diferent types of drivers released to theworldwide market since 1997. Our drivers have earned a reputation for their small size, low noise, high eficiency, and low cost, making them ideal for a wide range of applications. Our laser drivers are u

Analog Technologies has a long history of developing high-quality laser drivers, with over 100 diferent types of drivers released to theworldwide market since 1997. Our drivers have earned a reputation for their small size, low noise, high eficiency, and low cost, making them ideal for a wide range of applications. Our laser drivers are u